![]()

at Cutting-Edge of

Wireless Charging

The most Comprehensive Wireless

Charging Solution for AGVs

Are your factory's AGVs equipped for 24-hour automatic charging?

-

Type AMagnetic Resonance System

*Wireless charging is maintained without decreased efficiency even with a coil gap of several centimeters. This is the benefit of alignment flexibility. Furthermore, the Magnetic Field Resonance System is perfectly suited to the needs for transfer of large amounts of electric power in industrial usage. Alignment

flexibility*HIGH Safety HIGH Operation

costLOW Installation

costLOW -

Type BElectromagnetic Induction System

*A coil gap of more than 1cm will lead to a failure to charge, making alignment complex leading to a potential increase in operational costs. Alignment

flexibility*LOW Safety HIGH Operation

costHIGH Installation

costHIGH -

Type CContact Charging System

*There is a need for direct contact in charging which can lead to machine deterioration as well as high operation and maintenance costs. Alignment

flexibility*LOW Safety LOW Operation

costHIGH Installation

costHIGH

The world's first Type A (Magnetic Resonance System) and most practical wireless charging system for industrial applications.

- 100% Charging Rate Success

- Maximum 86% System Efficiency

- A clear path to ROI

- Unparalleled Charging Speed

- Realizing 24-hour Operation

*as of October 2017

The Revolution in

Charging Systems

- Japanese technology realizing 100% charging rate success

- Magnetic resonance system allowing long-distance power transfer*

*Daihen is an official WiTricity licensee

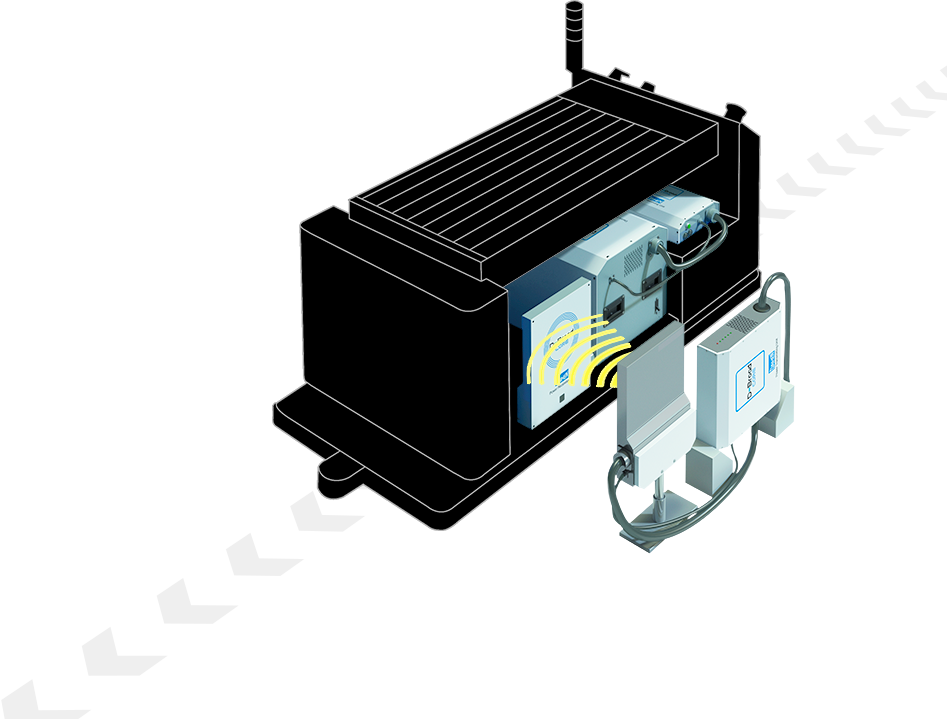

Through the combination between the electric energy specialists DAIHEN and the patented coil technology of Electricity, D-Broad allows for an charging area that is unchallenged in its width. It allows for wireless charging with a maximum gap of 40mm for power receiving & transmission, while the AGV can be stopped with a gap up to 10mm. D-Broad has a charging success rate of 100% (a charging failure = stoppage of the AGV). Until now, a charging failure complaint has not been registered from any of our customers.

Unparralled Safety

& Productivity

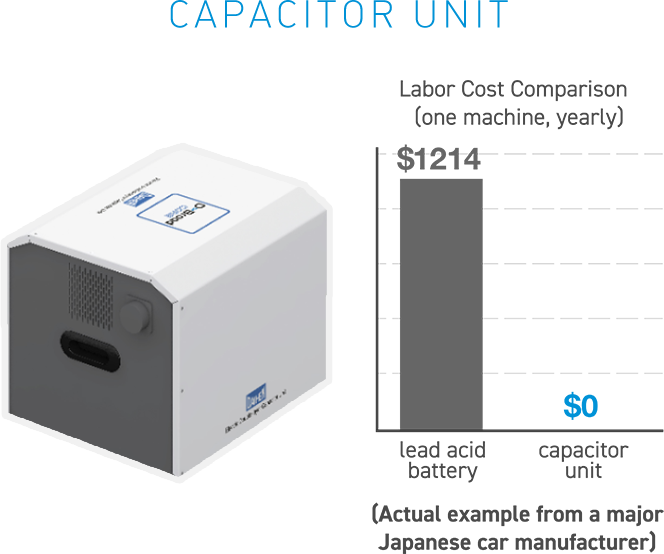

- Realizing 24-hour operation without labor needs

- High-speed charging of max. 60A*

- Easy to install to existing AGVs

*Through utilizing of an optional capacitor

By simply inserting our technology to the AGV to be charged as well as installing a charging point at the AGV's stoppage area, there is no need to purchase a specialized AGV. Adopting our capacitor allows for high-speed transfer of power, meaning that by installing charging coils at a position where the AGV is unloading can lead to seamless charging during the unloading process. This also eliminates the need for daily charging, battery replacement as well as trouble from the occurrence of electric shocks.

A clear path to ROI

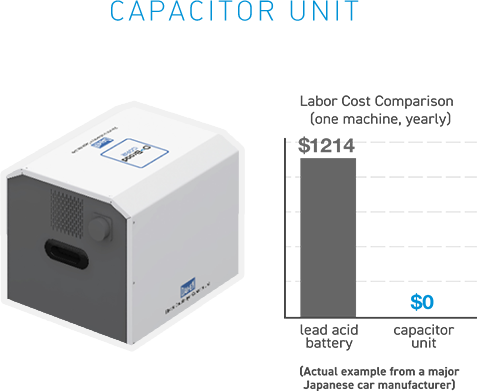

- ROI possible within 2 years*

*Through utilization of a solution featuring the wireless charging system & capacitor

*Actual example of a major Japanese car manufacturer

Initial investment and annual running costs largely vary by the combination of charging system and power storage device.

Requirements for estimate workload:

9 large AGVs (wired charging through changing the battery) equivalent to $26,500

Operating time:

In 8 hours, 3 substitutions are necessary

Number of power transfer units:

4 sets/9 units

DAIHEN's wireless power transfer system for AGV (a solution that combines the wireless power transfer system with a capacitor) ensures payout within two years.

Achieving Real

Cost Reduction

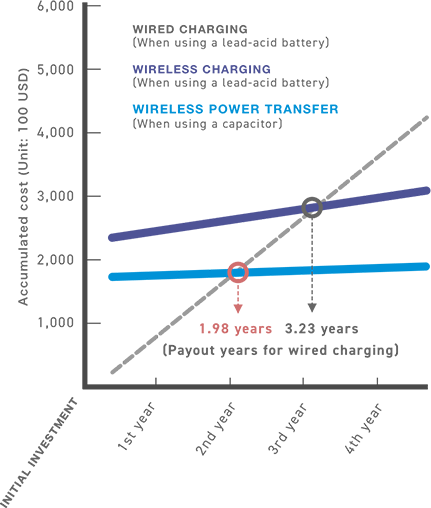

- Cutting energy-related costs at your factory or warehouse

- The industry's highest standard for wireless charging efficiency

- More efficient than wired solutions

In the development process, DAIHEN has achieved advances in power transfer resulting in an increased charging efficiency from below 50% to above 86%. Even with some gaps in positioning, charging efficiency of 86% was maintained.

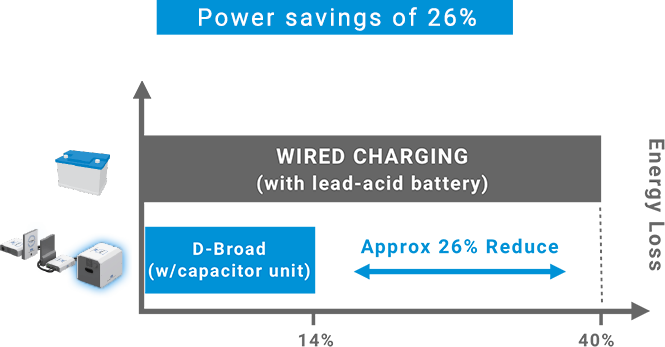

By using a capacitor unit together with the power storage device, a reduction in energy loss of 26% is possible. There have also been cases where a yearly reduction in electricity costs and CO2 emissions of up to 60% were achieved.

TECHNOLOGY & NETWORK

Why DAIHEN?

Established in 1919, DAIHEN is a Japanese electrical infrastructure company that has managed continued contributions to the global manufacturing industry. It is the only company that is doing business with all of Japan's Top 10 electrical power companies. Thriving in an industry with strict product expectations, DAIHEN has managed to hold the global top share in welding robots, while occupying the top Japanese share in transformers & welding machines. DAIHEN prides itself in not simply selling its products, but to work together with customers to revolutionize their operation. The company has managed to expand to provide its products & services to major manufacturers globally.

VISION

Turning a Vision

into Reality

Wireless Power Transfer System Div.

General Manager

YOSHINORI TSURUDA

At DAIHEN, we are proud to have been able to develop the world's first magnetic resonance wireless charging system for industrial applications, through which we believe the modern factory will be revolutionized. We released our wireless charging system for AGV use in April of 2016 and have been overwhelmed by the positive reaction - on a global scale - from our customers. Our next mission is to expand our lineup for wireless charging solutions further, with various target applications including electric vehicles in planning.

Please enjoy this concept video for

EV applications.

TESTIMONIALS

Revolutionizing Manufacturing Sites, 1 by 1

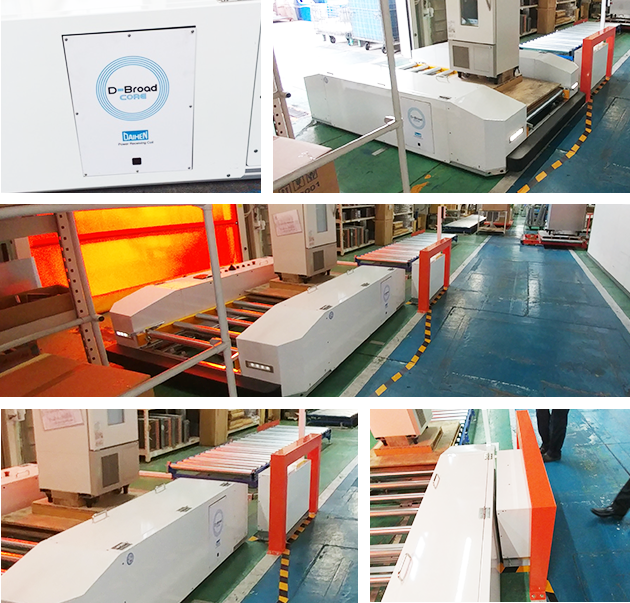

"We could not be more pleased with our decision to install 2 types (standard-type and slim-type) of DAIHEN's D-Broad CORE at our Okayama factory, a decision we came to with the goal of increasing production capability as well as realizing increased automation.

Through implementing the capacitor unit as a power storage device, we achieved high-efficiency, high-speed charging during the AGV's operation. Furthermore, this eliminated the need for daily manual charging, as well as the need to change deteriorating lead-acid batteries.

Implementing D-Broad helped us achieve our goals with respect to factory automation and improved productivity, with an added bonus of being environmentally friendly."

Commercial Refrigerator Business Fukushima Industries Corp. Okayama Factory Industrial Science Department

Our Line-up

-

SPECIFICATIONS

SPECIFICATIONS

Power transmitting unit Number of phases: 3, 50/60 Hz, 200/220 V ± 10 %, 4 kW Power receiving unit 12 to 57 V, Maximum 60 A Power transmitting unit External dimensions

(W×D×H)343×421×130 mm

(Excluding protrusions)Weight 7.5 kg Power receiving unit External dimensions

(W×D×H)261×354×80 mm

(Excluding protrusions)Weight 4 kg Power transmitting coil unit External dimensions

(W×D×H)290×66×396 mm

(Excluding protrusions)Weight 3 kg Power receiving coil unit External dimensions

(W×D×H)290×66×396 mm

(Excluding protrusions)Weight 3 kg External dimensions

(W×D×H)

(Excluding protrusions)Weight Power transmitting unit 343×421×130 mm 7.5 kg Power receiving unit 261×354×80 mm 4 kg Power transmitting coil unit 290×66×396 mm 3 kg Power receiving coil unit 290×66×396 mm 3 kg -

SPECIFICATIONS

SPECIFICATIONS

Power transmitting unit Number of phases: 3, 50/60 Hz, 200/220 V ± 10 %, 2 kW Power receiving unit 12 to 60 V, Maximum 30 A Power transmitting unit External dimensions

(W×D×H)343×421×130 mm

(Excluding protrusions)Weight 7.5 kg Power receiving unit External dimensions

(W×D×H)355×183×50 mm

(Excluding protrusions)Weight 2.5 kg Power transmitting coil unit External dimensions

(W×D×H)380×38×150 mm

(Excluding protrusions)Weight 3.7 kg Power receiving coil unit External dimensions

(W×D×H)380×38×150 mm

(Excluding protrusions)Weight 3.6 kg External dimensions

(W×D×H)

(Excluding protrusions)Weight Power transmitting unit 343×421×130 mm 7.5 kg Power receiving unit 355×183×50 mm 2.5 kg Power transmitting coil unit 380×38×150 mm 3.7 kg Power receiving coil unit 380×38×150 mm 3.6 kg -

SPECIFICATIONS

SPECIFICATIONS

Power transmitting unit Number of phases: 1, 50/60 Hz, 200/220 V ± 10 %, 1.3 kW Power receiving unit 12 to 30 V, Maximum 20 A Power transmitting unit External dimensions

(W×D×H)340×230×150 mm

(Excluding protrusions)Weight 8 kg Power receiving unit External dimensions

(W×D×H)145×135×80 mm

(Excluding protrusions)Weight 1.6 kg Power transmitting coil unit External dimensions

(W×D×H)230×45×155 mm

(Excluding protrusions)Weight 2 kg Power receiving coil unit External dimensions

(W×D×H)210×45×155 mm

(Excluding protrusions)Weight 1.5 kg External dimensions

(W×D×H)

(Excluding protrusions)Weight Power transmitting unit 340×230×150 mm 8 kg Power receiving unit 145×135×80 mm 1.6 kg Power transmitting coil unit 230×45×155 mm 2 kg Power receiving coil unit 210×45×155 mm 1.5 kg

CONTACT US

For more information on our products for AGVs including setting up product demonstrations

as well inquiries regarding joint development, please use the form below.

Please fill out the required fields.